Update Your Tools Collection: Discover the Best Dirt Screen for Sale in the Market

Enhance Product Recovery With State-Of-The-Art Dust Screens for Recycling Facilities

In today's globe, where environmental sustainability is a pressing worry, reusing centers play a pivotal duty in reducing waste and saving sources. However, optimizing material healing can be an intricate procedure, typically hindered by the presence of dirt and particles in the reusing stream. This is where advanced dust displays enter play, offering an appealing option to boost product recuperation prices. By efficiently separating unwanted contaminants, these advanced screens hold the possible to change reusing centers' procedures. Exactly how precisely do dirt screens improve material recovery? What are the crucial features that make them state-of-the-art? And exactly how can recycling facilities implement them efficiently? In this discussion, we will certainly explore the answers to these inquiries and dive right into real-life situation researches that highlight the effective combination of dirt screens in reusing centers. Prepare to uncover the transformative power of advanced dirt screens and their influence on boosting product healing.

The Importance of Dust Screens in Recycling Facilities

Dirt displays play an important function in reusing centers by efficiently dividing dust and various other pollutants from recyclable products. These screens, additionally known as trommel screens, are created to efficiently get rid of unwanted debris and make certain that only tidy and usable materials are refined even more.

The primary function of dust displays is to separate larger pieces of dirt, rocks, and various other non-recyclable things from the stream of products. By doing so, they prevent these impurities from going into the reusing process and possibly damaging devices or jeopardizing the top quality of the last product.

Furthermore, dust displays aid to enhance the total efficiency of recycling operations. By eliminating dust and various other impurities early at the same time, the displays decrease the amount of manual labor needed to sort and clean the materials later. This not only saves time but also minimizes prices and boosts performance.

Moreover, using dirt screens adds to ecological sustainability. By making certain that just tidy and unpolluted products are refined, recycling centers can generate higher-quality recycled items. This, consequently, motivates the use of recycled products in various industries, decreasing the need for virgin sources and decreasing the ecological influence of resource removal and production processes.

How Dust Screens Improve Product Recuperation

Utilizing dust screens in recycling centers substantially improves the process of product healing. These screens play a crucial duty in dividing dirt, particles, and other unwanted materials from the recyclable stream, causing enhanced efficiency and greater top quality outcome.

One of the major methods which dust screens boost material recuperation is by removing contaminants that can prevent the recycling process. Dust, rocks, and other non-recyclable items can create damage to tools, minimize the efficiency of subsequent sorting procedures, and pollute the last recycled materials. By efficiently screening out these impurities, dirt displays help ensure that the recyclable materials continue to be pure and of high quality.

Furthermore, dust displays make it possible for recycling centers to recover a higher quantity of valuable materials. By getting rid of dirt and particles, the displays permit a much more exact sorting procedure, enhancing the recuperation rate of recyclable materials. This suggests that better resources can be redeemed and reused, minimizing the demand for virgin materials and decreasing the environmental effect connected with their extraction and production.

In enhancement to boosting material recovery, dust displays also contribute to the general effectiveness of recycling facilities. By protecting against equipment damage and minimizing downtime triggered by obstructions and obstructions, these displays assist preserve a nonstop and smooth recycling procedure. This increased effectiveness equates right into expense savings and permits higher throughput, eventually improving the success and sustainability of reusing procedures.

Trick Attributes of State-of-the-Art Dust Screens

To further enhance the efficiency and effectiveness of material recuperation in recycling facilities, state-of-the-art dust displays are outfitted with key features that maximize the splitting up procedure and guarantee the finest outcome (dirt screen for sale). These functions include innovative screening technology, personalized setups, and durable building and construction

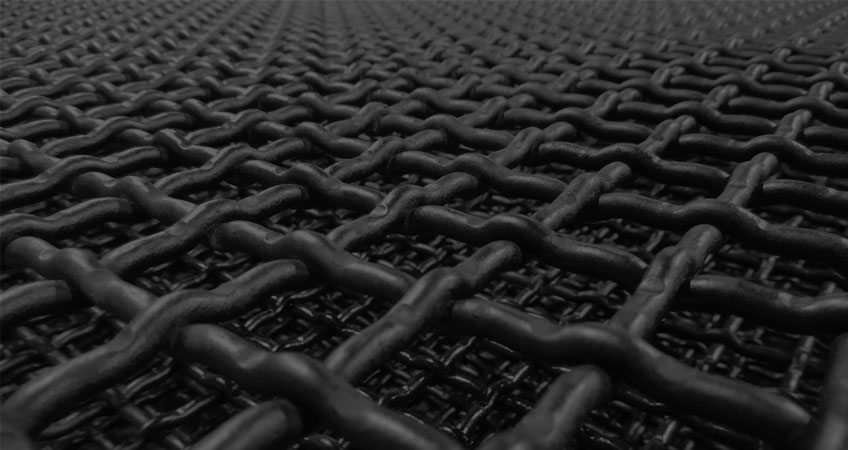

One trick attribute of advanced dirt screens is their sophisticated screening technology. These displays are created with precision-engineered mesh or perforated plates that successfully different dust and debris from the recyclable products. The size and spacing of the openings in the screens can be personalized to fit various kinds of materials, permitting effective splitting up and maximum recovery prices.

Another important attribute of these dirt displays is their adjustable settings. Recycling centers can adjust the rate, angle, and amplitude of the screens to enhance the splitting up process. This adaptability allows drivers to adjust the displays according to the specific needs of the materials being refined, resulting in improved precision and higher recuperation rates.

In addition, modern dirt displays are built with robust building and construction to withstand the harsh problems of reusing facilities. They are made from long click over here lasting materials such as stainless-steel or high-strength alloys, guaranteeing long life and minimal downtime due to upkeep or repair work. In addition, these displays are developed with very easy gain access to for cleansing and maintenance, assisting in reliable operations and decreasing downtime.

Actions to Applying Dust Screens in Recycling Facilities

What are the essential steps for including dust screens right into reusing centers? Executing dirt screens in recycling facilities includes a systematic strategy to ensure efficient setup and procedure. The adhering to are the needed actions to efficiently include dust screens:

Analysis: Conduct a comprehensive evaluation of the facility's demands and requirements to figure out the proper dust display specifications. Think about elements such as material type, volume, and preferred separation efficiency.

Setup: Prepare the center for the installation of the dirt displays. This might include retrofitting existing tools or creating area for brand-new installments. Follow producer standards and make certain proper positioning and integration with the reusing procedure.

Examining and Calibration: Once the dust screens are mounted, perform extensive screening to make certain correct functioning. dirt screen for sale. Adjust the system to attain wanted splitting up efficiency and reduce material loss

Training and Upkeep: Train team on operating and keeping the dust display system. check out here Develop a regular upkeep timetable, consisting of cleaning and assessment, to make certain optimum efficiency and long life.

Instance Research Studies: Effective Material Recuperation With Dust Screens

Integrating dust screens right into reusing facilities has actually verified to be an effective technique for attaining efficient product recuperation, as shown by a number of case research studies. These study highlight the positive impact of dirt displays on the total recycling process.

By implementing dirt screens, the facility was able to substantially reduce the quantity of contamination in their recyclable products. The intro of dust screens likewise assisted to tear and lessen the wear on arranging devices, lowering upkeep expenses and downtime.

One more situation research study showcases a rural recycling facility that fought with too much dust and particles in their incoming waste stream. By setting up dirt screens, the facility had the ability to get rid of a huge part of the undesirable materials, causing cleaner recyclables and boosted performance in the arranging procedure. This led to greater product healing rates and reduced waste sent out to the garbage dump.

These study show that including dirt screens right into recycling centers can have a substantial positive influence on material recovery. By properly getting rid of dirt, particles, and various other pollutants, reusing facilities can enhance their overall recycling prices, minimize landfill waste, and make the most of the value of retrieved materials.

Conclusion

In verdict, using advanced dirt displays in recycling centers is vital for improving material recuperation. These screens properly eliminate dirt and particles, enabling the reliable separation and recuperation of useful materials. By executing dirt displays, recycling facilities can significantly enhance their reusing processes and add to a much more lasting future.

One of the main methods in which dust displays enhance product healing is by eliminating pollutants that can hinder the reusing process. By properly screening out these contaminants, dust screens aid ensure that the recyclable materials continue to be pure and of high quality.

Furthermore, dirt displays make it possible for recycling facilities to recoup a higher amount of valuable materials.In enhancement to boosting material recuperation, dirt screens likewise add to the general efficiency of reusing centers.In conclusion, the use of advanced dust displays look at this web-site in recycling centers is critical for enhancing material recovery.